ERP vs CRM for Manufacturing: What’s the Difference and Why You Need Both

In today's hyper-competitive manufacturing landscape, American companies are under constant pressure to reduce costs, improve customer satisfaction, and streamline production. Yet, many still rely on disconnected systems—or worse, spreadsheets—to manage critical business processes. That’s where ERP CRM integration comes in.

For manufacturing businesses in the USA, Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) systems are no longer optional. These platforms offer two sides of the same coin—streamlining internal operations while optimizing customer engagement. But what exactly is the difference between ERP and CRM for manufacturers? And why is integrating both essential for long-term success?

Let’s dive into the details.

What is ERP in Manufacturing?

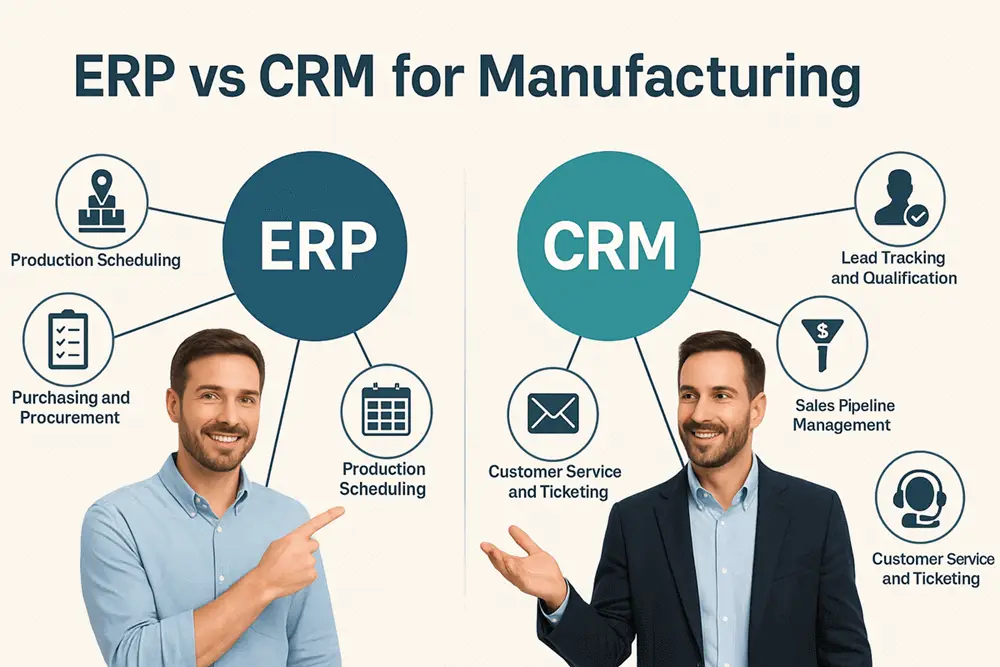

Enterprise Resource Planning (ERP) is a software solution designed to streamline and manage essential business processes. For manufacturers, ERP typically handles:

- Inventory and supply chain management

- Production scheduling

- Purchasing and procurement

- Work order tracking

- Finance and accounting

- Quality control

- Compliance and reporting

In essence, ERP helps manufacturing businesses optimize resources—from raw materials to manpower—so they can produce goods efficiently, on time, and within budget.

Example: A custom furniture manufacturer in Ohio uses ERP to automatically reorder wood and hardware based on sales forecasts and stock levels. This minimizes downtime while keeping overhead low.

What is CRM in Manufacturing?

Customer Relationship Management (CRM) systems focus on managing interactions with current and prospective customers. While ERP looks inward, CRM looks outward. Key CRM features include:

- Lead tracking and qualification

- Sales pipeline management

- Customer communication logs

- Marketing automation

- Customer service and ticketing

- After-sales support

For manufacturers, a CRM ensures your sales and customer service teams have full visibility into every customer relationship, from the first inquiry to the final delivery—and beyond.

Example: A machinery supplier in Illinois uses CRM to track every client’s maintenance requests and purchase history, ensuring timely follow-ups and upsell opportunities.

ERP vs CRM: A Quick Comparison:

| Feature | ERP | CRM |

| Focus | Internal operations | Customer-facing interactions |

| Modules | Inventory, production, finance | Sales, marketing, customer service |

| Users | Operations, finance, supply chain teams | Sales, marketing, customer service reps |

| Goal | Optimize resources and processes | Improve customer acquisition and retention |

While ERP and CRM serve different purposes, their ultimate goal is the same: business growth through operational efficiency and customer satisfaction.

Why U.S. Manufacturers Need Both ERP and CRM:

Now comes the big question: can manufacturers get by with just one of these systems?

The short answer: not if they want to scale efficiently and profitably.

Here’s why you need both:

1. 360-Degree Business Visibility

ERP tells you what's happening inside the factory—inventory levels, supplier delays, production metrics. CRM tells you what customers expect—delivery deadlines, service issues, new inquiries.

When you connect ERP and CRM, decision-makers can see the full picture.

Use case: A sales rep in California checks the CRM to see a customer's reorder request, then uses ERP data to confirm current inventory and delivery timelines before committing.

2. Enhanced Forecasting and Planning

With ERP CRM integration, manufacturers can better predict demand, align production schedules, and plan raw material purchases. CRM data provides insight into the sales pipeline, while ERP forecasts availability and lead times.

Insight: A Florida-based HVAC manufacturer reduces overproduction by aligning CRM’s deal forecasting with ERP’s MRP (Material Requirements Planning) module.

3. Improved Customer Experience

CRM systems ensure personalized communication. ERP systems ensure the product is built and delivered correctly. Together, they ensure a seamless customer experience from initial inquiry to final invoice.

Customer story: A Detroit-based auto parts supplier uses CRM to send order confirmations and service reminders, while ERP ensures real-time order tracking and accurate billing.

4. Stronger Sales and After-Sales Service

When sales and service teams can view ERP data—such as product specs, order status, or warranty information—they respond faster and with more precision. This enhances trust and opens doors to repeat business.

Example: A CNC machine tool company in Texas enables field service technicians to access ERP-generated maintenance schedules directly through the CRM interface.

5. Automation and Reduced Manual Work

Disconnected systems mean double data entry, which leads to errors and wasted time. ERP CRM integration automates data sharing—new customer entries, quotes, and invoices can flow between systems instantly.

Benefit: Sales teams don’t need to manually request pricing or production status from the operations department—it’s all available at their fingertips.

How ERP CRM Integration Works:

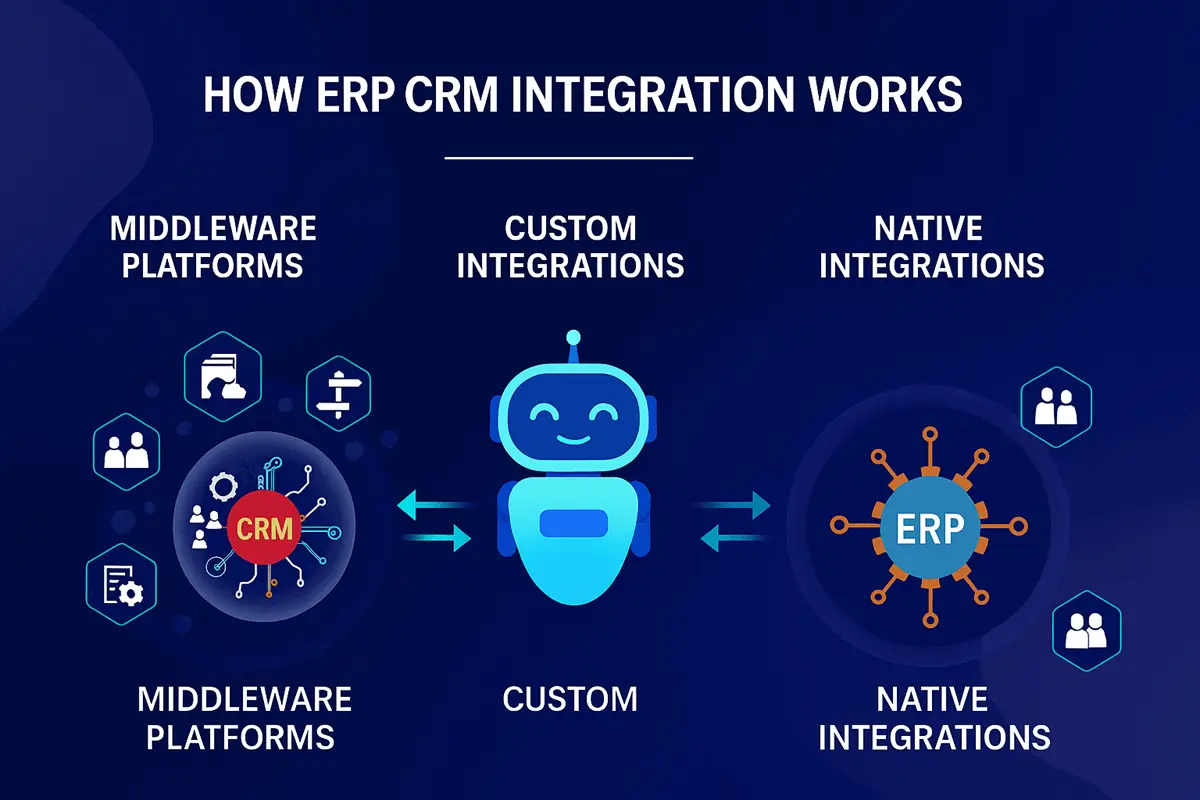

There are three common ways manufacturers can integrate ERP and CRM systems:

- Native Integrations: Offered by platforms like Microsoft Dynamics 365 or SAP, where ERP and CRM are built to work together.

- Middleware Platforms: Tools like Dell Boomi or MuleSoft that connect systems via APIs.

- Custom Integrations: Custom connections built by software development partners, ideal for unique workflows.

For U.S. manufacturers looking to compete globally and deliver locally, choosing the right integration model can be a game-changer.

Things to Consider Before Integration

Before jumping into ERP CRM integration, manufacturers should evaluate:

- Data consistency – Are product and customer records unified?

- User roles and permissions – Who needs access to what data?

- System compatibility – Can your ERP and CRM "talk" to each other?

- Customization Requirements – Do your workflows demand specialized fields or custom logic?

Selecting a technology partner with proven manufacturing expertise is essential for a smooth and efficient rollout.

Final Thoughts: Integration is No Longer Optional:

For modern manufacturers in the USA, digital transformation is no longer a buzzword—it’s a necessity. ERP CRM integration offers the tools to improve productivity, profitability, and customer satisfaction all at once.

Instead of managing production and customer relationships in isolation, manufacturers must embrace unified systems that empower their teams with real-time insights.

If your manufacturing business is still operating on disconnected software, now is the time to bridge the gap. Because when ERP and CRM work together, your entire business works smarter.

Would you like this converted into an HTML version, need meta tags, or want help creating a companion infographic or social teaser post? I can help with that next.

Brought to you by The Farber Consulting Group Inc. — Helping U.S. manufacturers accelerate growth with custom ERP and CRM development solutions. Call us to discuss further.

Comments