Prevent Stock-outs with Warehouse Inventory Management Software

Good warehouse inventory management software prevents stockouts, lost inventory, and waste. Production seldom stops so orders get delivered on time.

Inventory is at the heart of your supply chain, taking materials from your suppliers and pumping finished goods to your customers. If something goes wrong, everything throughout your entire system is affected.

This makes proper warehouse inventory management software vital to a smoothly run supply chain.

Inventory includes three levels of cost:

- The costs of materials, parts, and components.

- The costs to store, maintain, and move them to distribution.

- The costs of tying up your cash in items sitting in a warehouse, borrowing money to maintain inventory levels, and paying interest above the initial cost.

Inventory has five levels of risk:

- A stockout where there is no more of something. A component goes missing. Either way, you must freeze production until it is relocated or reordered.

- A production that puts sales on backorder forcing your customers to wait longer than expected.

- Impatient customers canceling their orders and buying from the competition.

- Customers abandon you altogether once they go to a competitor.

- Disgruntled customers taking to social media to tarnish your reputation for shoddy service.

This is the area of your business where everything is at stake.

Warehouse Inventory Management Software to Smooth Out Your Supply Chain:

Your inventory management touches countless day-to-day operations throughout your supply chain:

- Receiving

- Production

- Shipping

- Sales

- Cash on Hand

- Productivity

- Forecasting

The more you can unify and calibrate these operations to work in symphony with one another, the less inventory you will have to carry, the more cash on hand you will have for other functions throughout your supply chain, and the happier customers will be with fast production and delivery.

The right ERP System is the best way to achieve harmony throughout your supply chain.

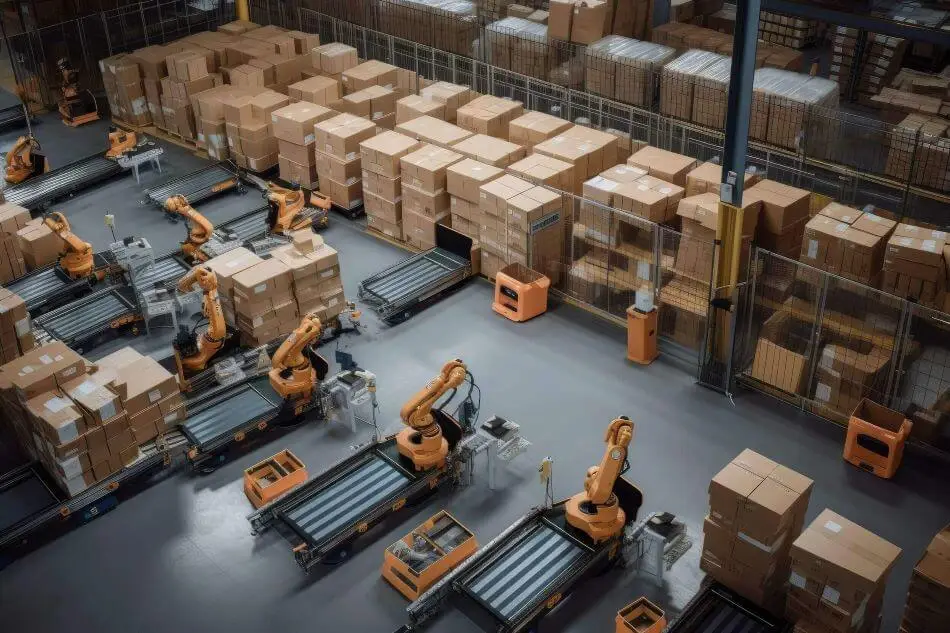

An Inventory Management System to Compete with the Big Boys:

You don’t need the budget of a General Electric or Dow Chemical to achieve productivity and efficiency like they do. If you have the right digital assets behind your production lines, you can be just as efficient, if not more.

This gives you a competitive advantage in the marketplace.

An Enterprise Resource Planning (ERP) platform takes all your software systems and puts them under one banner. Everything flows to and from a single database, so sales change is seen in forecasting, accounting, and even procurement.

This is ideal for any business that sells in waves where some times of the year are busier than others. It is perfect for growing companies where the demands and assumptions of every step in the supply chain are constantly changing.

The first step in digitalizing is warehouse inventory management.

The proper ERP Warehouse Management can do wonders for your business.

Operations that a Robust Inventory Management System Optimizes:

ERP Net is one of the premiere systems for managing your warehouse inventory. Its flagship feature is the ability to track where all your stock is, all the time.

It’s visual, making things easier for the user. You pull up a floor plan of your warehouse or storage area and enter an item.

The places where an item is located will light up in green. It can be a room, a specific closet, or even a shelf. You can find inventory immediately. As a custom-made platform, you can designate areas as rooms, closets, shelves, or even floor spaces (if there is no place to put something and put it in the nearest space).

When stock levels reach a certain point, you will be automatically alerted that you need replenishment. You can customize the actions you take next.

Using a web scraper, you can look for the best deals from different suppliers. You can alert your supplier that you need more or automate the entire process where your ERP Inventory Management tool immediately tells your supplier to ship you more at certain stock levels.

This can reduce, even eliminate, the danger of stockouts or pauses in production.

This also supports a just-in-time (JIT) inventory strategy to maximize your inventory turnover and minimize how much money is tied into raw materials. If you have to borrow to buy your inventory, you can save big on bank fees and interest payments.

Productivity gains spread throughout your supply chain as a finished good hit the shipping dock. Your system can send out the invoice, and at the same time, notify accounting to credit both sales and accounts receivable. Reductions in stock levels are recorded.

All of this data sits in a single database that you can analyze in real time. This is essential for forecasting quarterly sales, future purchases, and necessary storage space. As your business grows, every operation along your supply chain will scale out, changing the resource demands it has.

Real-time analysis keeps you a step ahead, enabling you to anticipate future needs and keep your customers happy without hiccups.

Saving your business time and money consistently with an ERP System customized to your business is what we specialize in. I am happy to talk with you about it at your convenience, so please do not hesitate to contact us.

Comments